Making - W289

Making of boulders W289A & W289B.

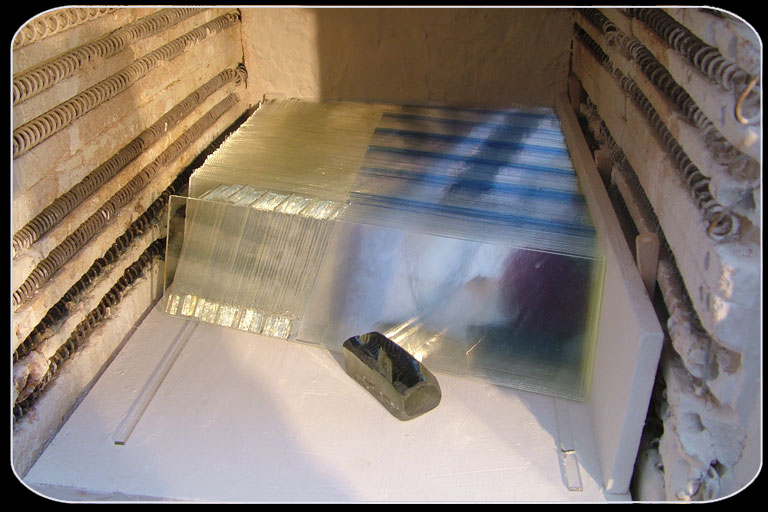

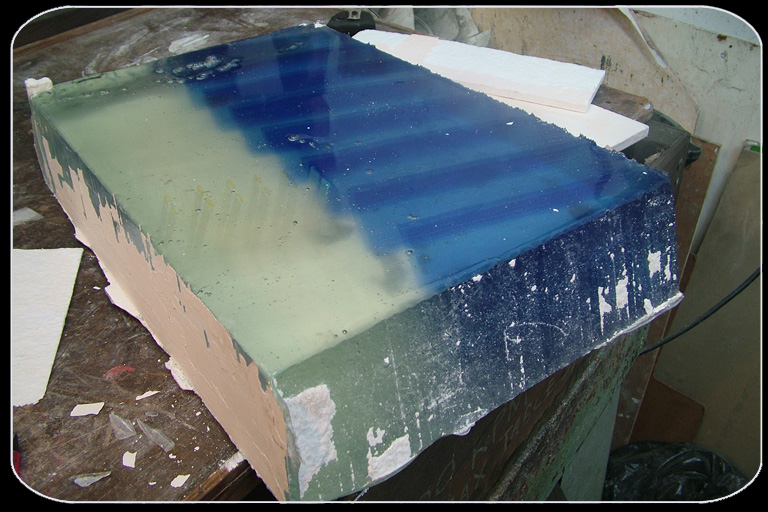

These pieces were fired together and then sawn up after firing.

This was done to make two entirely different pieces whilst utilising the ergonomics of cold assembly, which was done to save time on assembly, kiln space and anealing (cooling) schedules.

Assembly.

The block will be separated into two pieces.

W289A is on the left and W289B on the right.

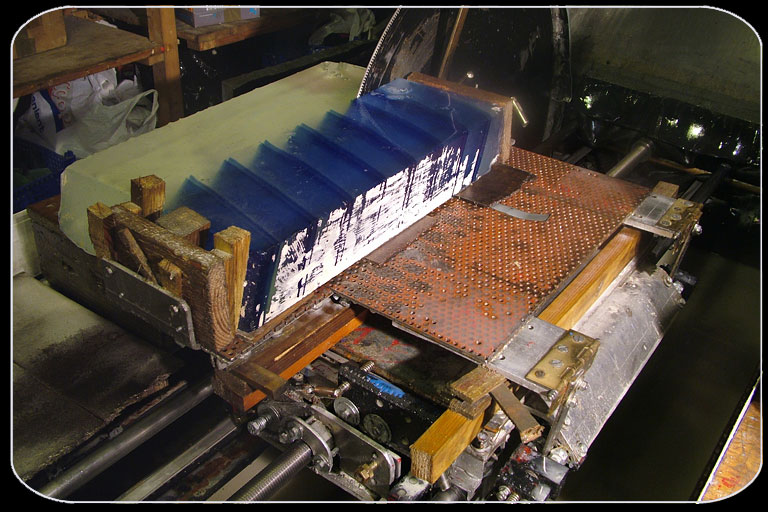

Separating the two pieces with a custom built saw.

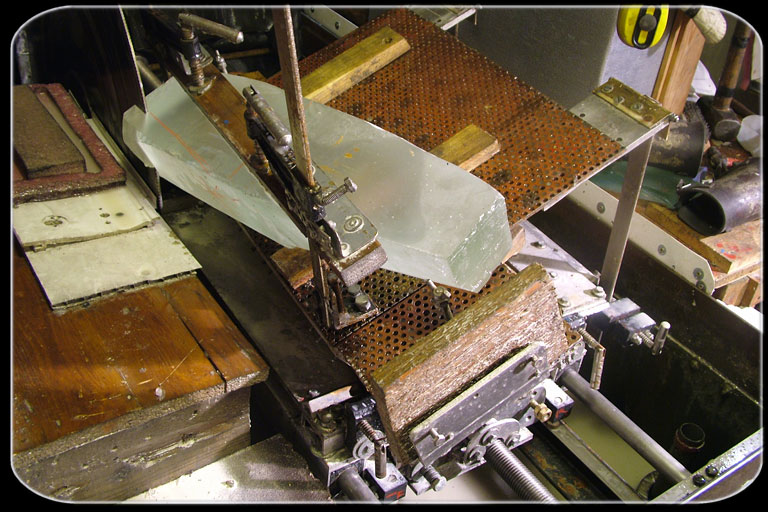

Shaping W289A with a custom built saw.

Grinding of W289B. The piece is ground using the sling counter balance (not really visible in this photo) to take the weight off heavy pieces.

A close up of the grinding shown above.

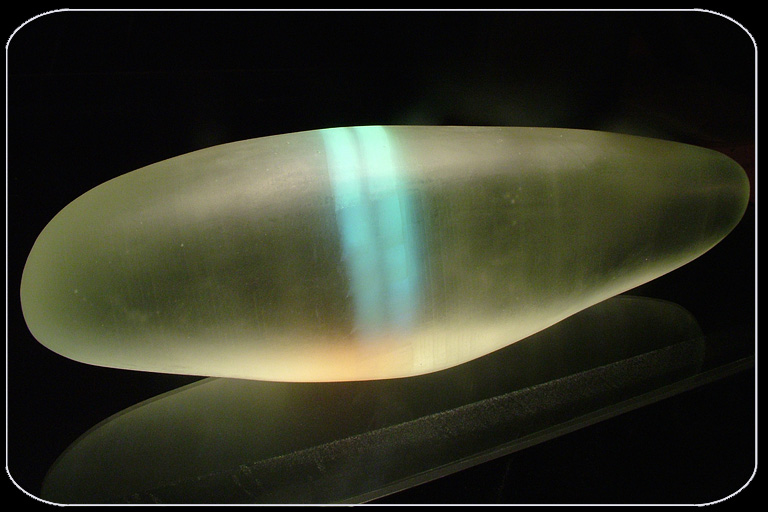

The finished piece W289A (click the photo to view details).

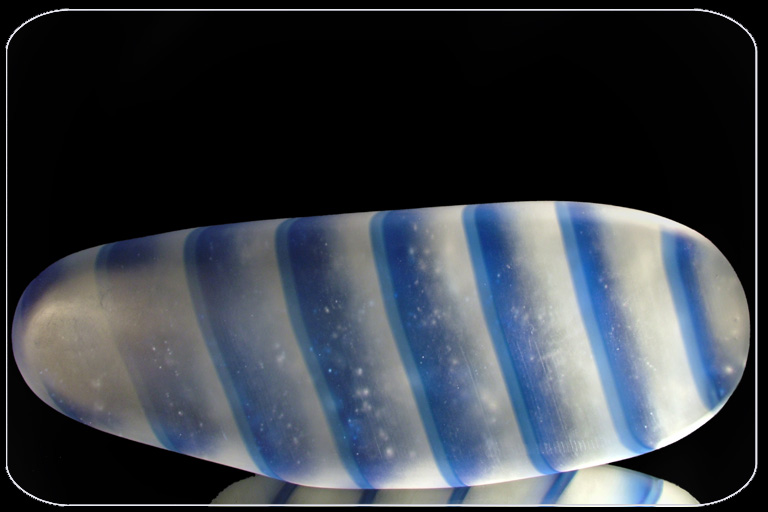

The finished piece W289B (click the photo to view details).